World-Class Performance Management System Uncovers the Hidden Factory and Unleashes Growth

The Situation

A global Chemical Manufacturer was dealing with a good problem – multiple years of sold-out product lines and a need to increase capacity fast. Considering regulatory and construction lead times of Capital projects and the unpredictability of long-term global demand, the company had to expand capacity by non-capital means.

Line managers felt that capacity was already maxed out – all internal KPIs were green and there seemed little opportunity for improvement.

The new COO hired ARGO-EFESO to challenge this capital dependent mindset and to uncover the ‘Hidden Factory’ by installing a performance management system that makes waste visible and sets the foundation for continuous improvement and the relentless pursuit of excellence.

ARGO-EFESO’s Actions

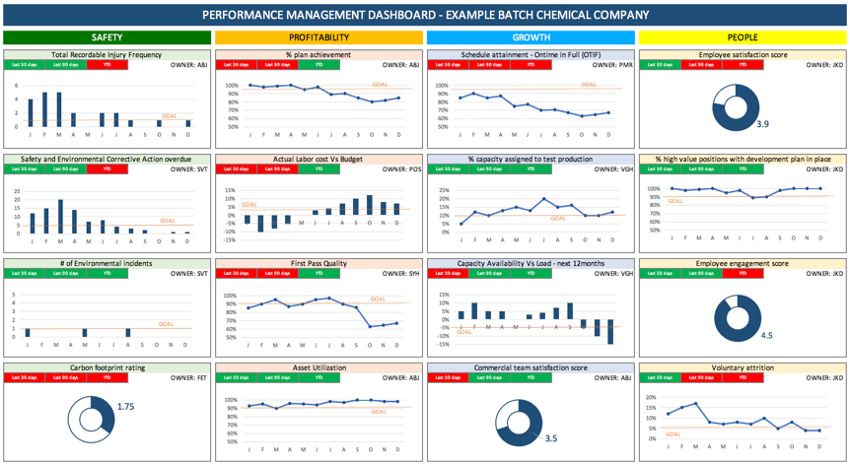

Drawing from 20+ years of Chemical and O&G industry experience, ARGO-EFESO established ‘meaningful’ KPIs for each level of the organization from the shop floor to the COO. Line managers felt the KPIs made sense as they were firmly rooted in chemical industry operational best practices.

Leadership found these KPIs to be the missing link between shop floor activity and company margin and profitability. They finally felt like we were speaking a common language.

With a framework in place, ARGO-EFESO embarked on the journey to change the culture. ARGO-EFESO challenged existing performance targets which we felt were conservative and made managers ‘look good rather than do good’.

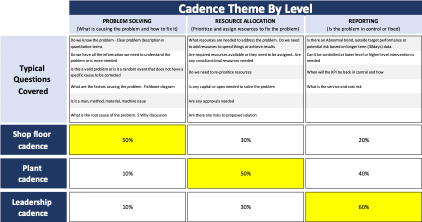

ARGO-EFESO connected each level of the organizational chain through a management cadence process – a set of checks and triggers to drive performance excellence. Based on the organizational level, cadence theme was set between – Problem Solving, Resource Allocation and Reporting. This targeted approach was more effective than the traditional ‘monthly review’ which often-times deviated to the hot topic of the day. Now, there was clear accountability for performance – KPI owners came prepared to engage in a fact-based discussion on variance and corrective actions.

Results

Within the first year of implementation, the company integrated the new Performance Management System into manager compensation and reward structure.

- The company increased revenue by $83 million and Gross margin by 10% with no increase in net asset base.

- Service performance, measured by schedule attainment (OTIF) improved from 85% to 98+%.

- Employees felt more connected to the mission and employee engagement score improved from 3.4 to 4.5

But more than anything, the new Performance Management System broke existing paradigms and transformed the culture. The company realized that to achieve excellence one needs to set aggressive goals, maintain transparency of performance and relentlessly work towards closing the gaps.

RESULTS AT A GLANCE

$83 MILLION

Revenue increase with same asset base

10% +

Gross margin improvement

98% +

Schedule attainment

4.5/5

Employee engagement score