A Medical Device Manufacturer Uses Value Engineering to Simplify New Product Development

Situation

ARGO-EFESO has been called by a medical device manufacturer of non-invasive osteoarthritis and injury solutions to implement a robust world-wide Value Engineering methodology. The client is going through a whole organizational change together with a new strategy deployment (called products simplified) and our 360° Value Engineering (VE) methodology was perceived as a perfect fit for this moment.

Throughout years, the client has acquired other medical companies and developed and launched new offerings creating complex portfolios overlapping products and features without cost concern given the market situation in the past. However, recently, the regulated public market for medical devices, mainly in the US, became more conscious about price and initiated competitive bidding that forced our client to dramatically review overall cost to keep their margins.

A major change in the new strategy was the focus on specific channels for the portfolio simplification: the prescribers which forced a completely new round of interviews through the “Voice of the Customer” to capture what they perceive as value. That new perspective was our “guideline” to redesign the portfolios.

In order to deploy the new strategy, all tasks related to new product development were placed on hold and the engineering teams were made available to work on the simplification of portfolios using our 360° VE approach.

Main objectives associated with the initiative were: overall cost reduction, quality improvement, product portfolio simplification, environmentally friendly design and sub-system/component standardization.

ARGO-EFESO’s Actions

ARGO-EFESO proposed a three-phase approach: pilot project, training and methodology deployment. Initially, two pilot projects were selected by the client. Due to the success of those first two pilot projects, a third one was added.

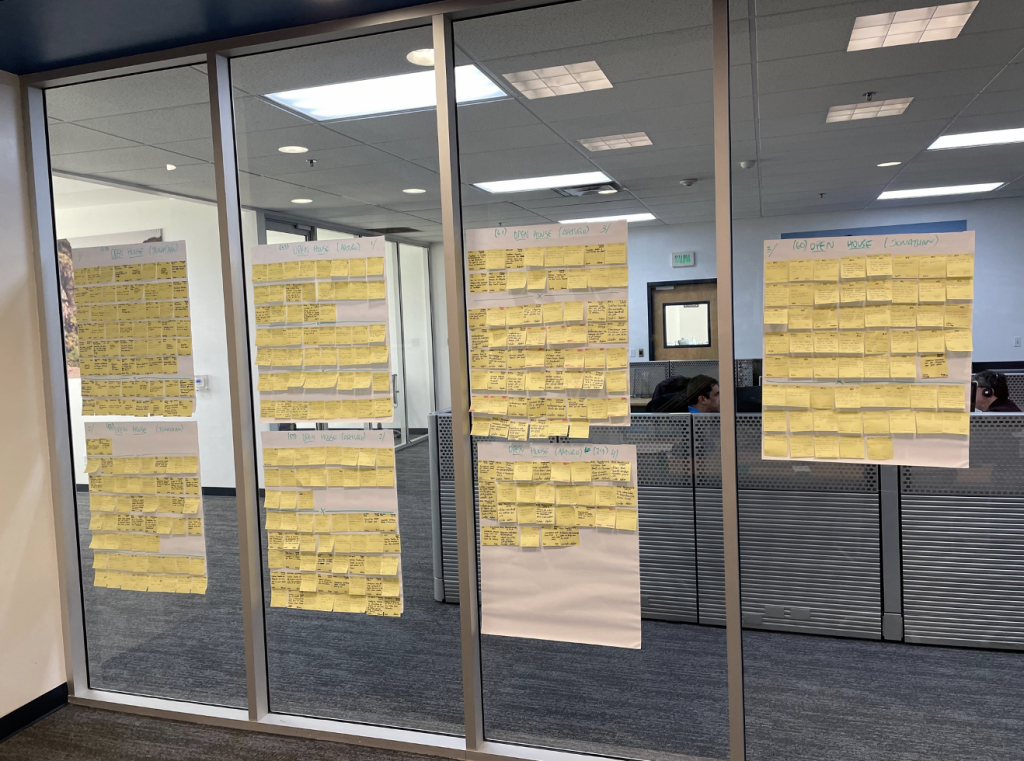

ARGO-EFESO’s Value Engineering Holistic 360° approach consists of the following steps as they apply to a given product family re-design: preparation, ideation, proposal development, consolidation and validation. Those steps, led by ARGO-EFESO, involve a cross functional team in a very collaborative positive atmosphere.

The 360° approach involves ideation from various sources:

1. Voice of the Customer: Understand brand differences and learn the technical interpretations of customer specifications and regulation changes;

2. DFM/DFA: Learn how design changes can improve manufacturing and/or assembly operations and define changes that can improve the manufacturing / assembly processes

3. Supply Chain: involve suppliers to learn their constraints, challenge the existent vertical integration, and Challenge origin of sourcing high-cost-countries (HCC) to best-cost-countries (BCC) or the other way around

4. Function Analysis: Define how the same function can be achieved in a different way (from function pareto analysis) at a higher value

5. Performance Teardown: Identify the weakest link in terms of performance and decide to either upgrade the weakest link or downgrade the performance of the rest

6. Benchmark: understand how competitors achieve the same functions, learn if competitors interpret the specifications and regulations differently, and perform “red tagging” on own and competitor products highlighting design differences

Additionally, to tackle product and feature overlap, a “design overlap” step was added to the process to optimize and simplify the offering that dramatically reduced the number of SKUs.

Our client is very satisfied with the results to date and sees the methodology as the new way of working in the future. Agreements were made to move the process to the next phases: training of 10 cross functional employees (including engineers, purchasing, project managers and product managers) and methodology deployment through additional two VE projects where ARGO-EFESO will be supporting the new trainees in properly delivering the methodology.

Results

- 20%+ cost reduction validated in all three pilot projects. Design changes to start deployment in 2022.

- Average of 1,000 ideas created per project during the process coming from different sources

- 300+ proposals developed per product portfolio

- 100+ proposals to be deployed in the short/mid-term per product portfolio

- 25%+ SKU rationalization

- Much simpler product portfolio offering aligned with customer needs

- All proposals evaluated considering a balanced choice between quality, environment impact and customer alignment