Operational Excellence: Driving Out Cost and Improving Reliability at a Chemical Plant

The Situation

- The company was under extreme pressure to reduce costs and improve EBITDA

- New leadership recognized the need for operational efficiency and to improve reliability. They also needed to improve plant operating performance, needing ARGO-EFESO to add speed and agility to this process

- Sustaining the gains was a top priority, and the goal was to engage the entire organization in the improvement activities

ARGO-EFESO’s Solution & Approach

- ARGO-EFESO leveraged our Best Run Chemical Operations Playbook and benchmarked the client against best practices and other clients in the industry to identify cost reduction and performance improvement opportunities

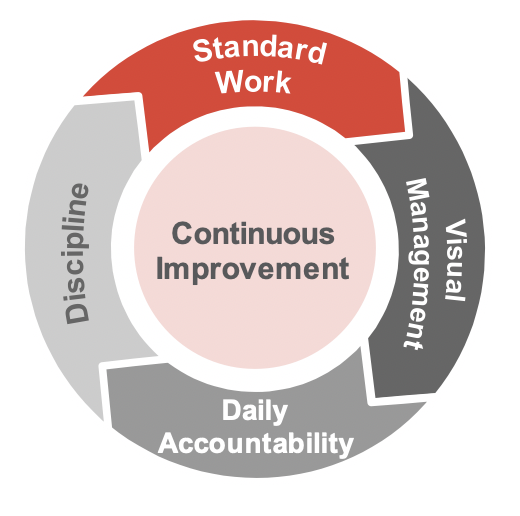

New Operating Models and Best Practices from ARGO-EFESO’s Best Run Chemical Operations Playbook were deployed to improve process and systems, and build a a culture of continuous improvement:

- Coaching Leadership for Success

- New Performance Management Operating System ( KPI driven)

- Benchmarking current state and defining future state

- New Best Practice Work Processes and Systems

- New well-defined roles & responsibility to drive ownership and accountability

- Implemented Continuous Improvement

- Established Visual Management

Key Workstream Drivers

- Developing leaders to take action and achieve lasting change through training and coaching

- Driving performance though metrics and cost accountability by area

- Organizationally changing the ownership of “Core Workflow” of equipment maintenance to operationally owned

- Operational Effectiveness to drive performance improvement of the assets and improve reliability – Maintenance and Reliability Strategies, Leader Walks, Operator Driven Maintenance

- Consolidation of soft crafts, and implementing metric driven productivity for third party contractors

- Improving processing departments of the Laboratory, Truck Loading Docks and Warehouse using lean principles

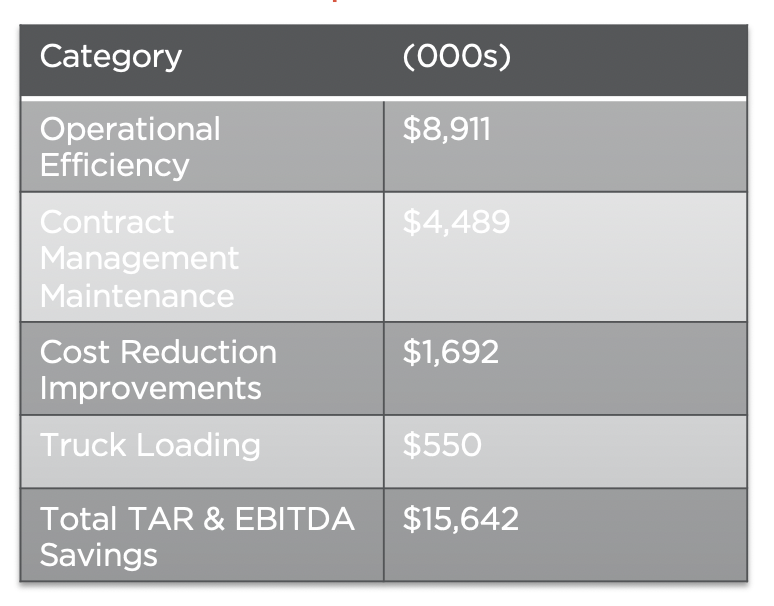

Impact Dollars

RESULTS AT A GLANCE

$15.6 MILLION

Annual pretax earnings improvements (10%)

40% to 90%

Increase in manpower utilization

100%

Load schedule for week vs daily

42% to 86%

Increase in schedule attainment

40% to 10%

Decrease in P1

50%

Increased truck loading